SMC Industries AU-1200 Reinforced Perlite Pipe Cover, Iron Pipe Size: 1/2 in IPS, Insulation Thickness: 2-1/2 in, Material: Perlite, Color: Gold, Density: 12 pcf, Application: For Use on Piping, Equipment and Vessels for Both Cyclic and Continuous High Temperature Applications up to 1200 deg F (650 deg C), It is Particularly Suited for Applications where CUI may be a Problem and is Preferred in Industrial Processing and Power Generation Plants for use on Austenitic Stainless Steels, Temperature Rating: 1200 deg F, Flame Spread Index: 0, Smoke Developed Index: 0, Compressive Strength: 90 to 110 psi, Flexural Strength: 80 to 105 psi, Thermal Conductivity: 0.4 to 0.9 Btu-in/hr-sq-ft-deg F

Application : For Use on Piping, Equipment and Vessels for Both Cyclic and Continuous High Temperature Applications up to 1200 deg F (650 deg C), It is Particularly Suited for Applications where CUI may be a Problem and is Preferred in Industrial Processing and Power Generation Plants for use on Austenitic Stainless Steels

Color : Gold

Compressive Strength : 90 to 110 psi

Density : 12 pcf

Flame Spread Index : 0

Flexural Strength : 80 to 105 psi

Insulation Thickness : 2-1/2 in

Iron Pipe Size : 1/2 in IPS

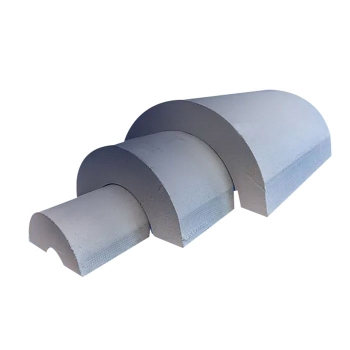

Item Name : Perlite Pipe Cover

Material : Perlite

Smoke Developed Index : 0

Sub Brand : AU-1200

Temperature Rating : 1200 deg F

Thermal Conductivity : 0.4 to 0.9 Btu-in/hr-sq-ft-deg F

Type/Style : Reinforced

SMC's AU-1200 was uniquely designed and formulated to offer an easier to handle and higher performing perlite silicate insulation. AU-1200 is a molded high temperature insulation that is hydrophobic, non-wicking, and contains leachable silicates proven to inhibit corrosion on the outer surfaces of piping and equipment. In addition, AU-1200 is manufactured with a patent-pending reinforcement applied to the outer surface of the insulation. The reinforcement provides the product with significant strength compared to standard perlite silicate, offering an ASTM C-610 compliant perlite silicate insulation that is easier to handle and less prone to breakage and friability than other products on the market. AU-1200 is the only insulation to offer the proven benefits of perlite silicate in a strong, robust structure that is easily shipped and handled. SMC produces AU-1200 in the USA with a brand new, highly automated manufacturing line based on decades of experience in the manufacture of perlite silicate. With a wide range of applications, SMC's AU-1200 delivers proven defense against CUI that is both effective and economical.

- Meets or exceeds ASTM C-610 standards

- Novel formulation based on decades of experience with perlite silicate insulations

- Patent-pending reinforcement provides the benefits of perlite silicate with increased strength, better handling and reduced friability

- Hydrophobic, non-wicking - helps prevent intrusion of water into the insulation system and keeps piping and equipment dry

- Inorganic and non-combustible - the binder maintains its integrity throughout its service temperature

- Strength and durability of a rigid insulation

- AU-1200 is 100% asbestos free and is manufactured with an easily recognizable gold coloration to provide an asbestos free identify system

- Specialized packaging to further decrease breakage and friability during shipping

- AU-1200 is designed to nest from the factory, making multi-layer applications simple and hassle-free

- When combined with SMC's molded perlite fitting covers, AU-1200 provides a complete preformed perlite silicate industrial insulation system that is ready to install out of the box

- Proven to inhibit corrosion - decades long track record of mitigating CUI, even in harsh environments with high humidity and rainfall

- In addition to water repellency, AU-1200 contains sodium silicates, which are chemically attracted to metals, forming a protective coating that guards against corrosive elements

- Inhibits stress corrosion cracking on austenitic stainless steel - seals out moisture and chlorides

- An economical solution - defense against CUI that is both effective and efficient

Standards/Certifications: ASTM C610|ASTM C442|ASTM C165|ASTM C203|ASTM C303|ASTM C356|ASTM E84|ASTM E136|ASTM C1763|ASTM C795|ASTM C692|ASTM C871|ASTM C1617|ASTM C335

SDS

SDS