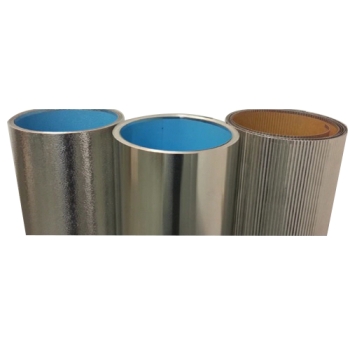

JM (Formerly Pabco/Childers) Stainless Steel Roll Jacketing, Item Thickness: .010 in, Material: T304 Stainless Steel, Finish: Smooth, Vapor Barrier: No, Length: 50 ft, Width: 36 in, Application: For Chemical Plants and Refineries, Paper Mills, Steel Mills and Miscellaneous, Tensile Strength: 75000 to 110000 psi

Application : For Chemical Plants and Refineries, Paper Mills, Steel Mills and Miscellaneous

Finish : Smooth

Item Name : Stainless Steel Roll Jacketing

Item Thickness : .010 in

Length : 50 ft

Material : T304 Stainless Steel

Tensile Strength : 75000 to 110000 psi

Vapor Barrier : No

Width : 36 in

ITW's stainless steel roll jacketing is manufactured from T-304 and T-316 prime grade stainless steels. These alloys comply with ASTM A240 and are supplied with a regular dull finish for reduced glare. The yield strength is 30000 to 45000 psi and the tensile strength is 75000 to 110000 psi. These alloys are of a special soft annealed temper, for ease in fabrication. T-304 is normally used in all except the most corrosive areas, where T-316 is recommended. The 300 series stainless steels have a melt point of approximately 2500 deg F, providing optimum fire protection. Stainless steel has a higher emittance value than aluminum and has physical properties superior to all other metal used as insulation protective jacketing. T-304 contains 18% chromium and 8% nickel. T-316 contains 16.5% chromium, 10% nickel and 2.2% molybdenum.

Standards/Certifications: ASTM A240

Technical Data Sheet

Technical Data Sheet